Safety: it is possible to spot the fluid leakage during the test of the installation if the fitting is not pressed.

Ideal system for the distribution of drinking water.

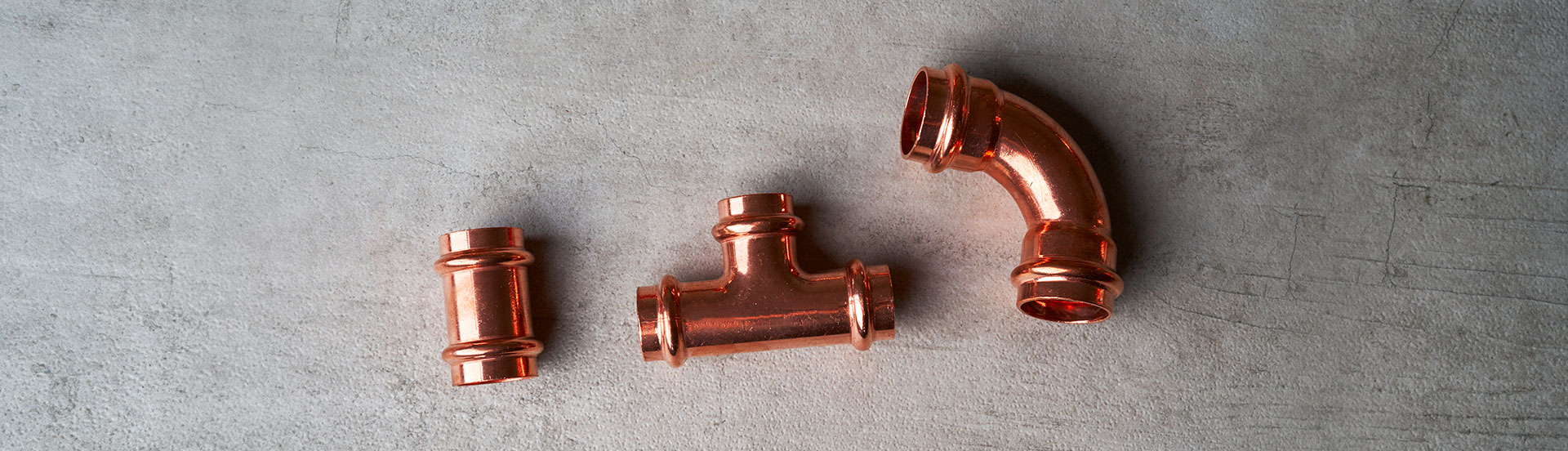

Easy and quick installation, typical of pressing technique.

Corrosion resistance, hygiene, and reliability.

Gaskets can be fitted without welding, eliminating the risk of fire in more hazardous situations (working in older buildings, furnished rooms, etc.).

No need for dangerous gas pumps or containers, eliminating the need to make the connections required by law.

Elimination of all welding materials, with inevitable cost benefits.

Junctions free from burning or rings with an excellent immediate visual impact.

Integrity of pipe insulation thanks to the absence of heat sources.

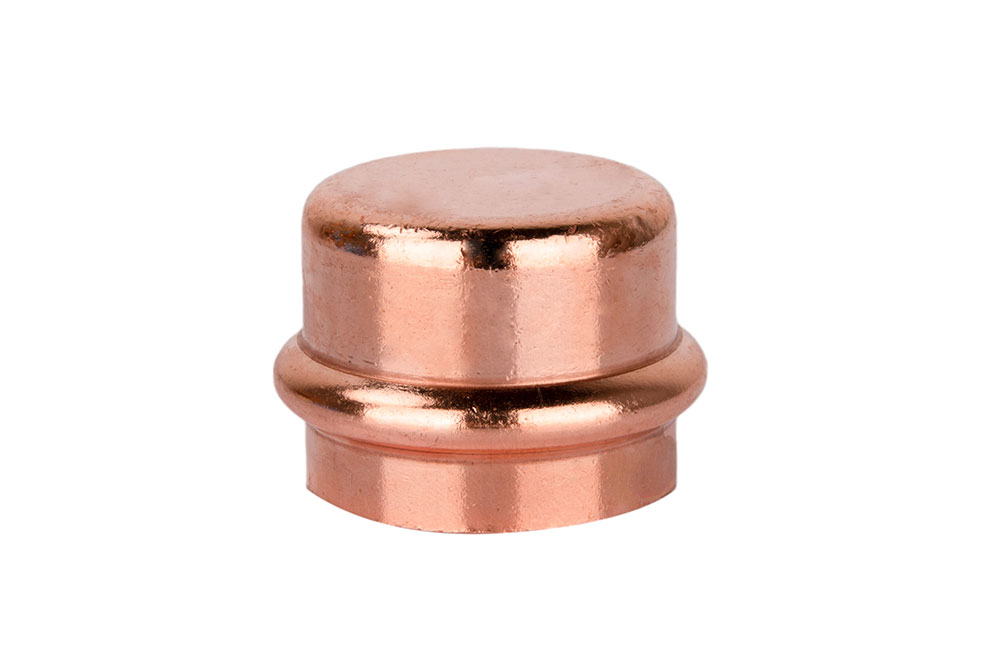

Increased wall thickness to ensure the reliability and durability of junctions and fittings.

Secure pipe-to-fitting connection thanks to the cylindrical guide on fittings both in front of and behind the O-ring.

Polygon-shaped press designed to ensure maximum resistance to traction and torsion stresses.

Precision cleaning of internal surfaces to eliminate oily residues due to processing and to ensure protection against rust under all operating conditions.